Much has been talked about cost reduction and process improvement, and organizations globally look at Process Re-engineering to help augment bottom-lines and profitability. As opposed to downsizing and continuous improvement, Business Process Re-engineering (BPR) is the only approach that can quickly achieve dramatic and permanent improvements. However, what is important to be noted is that not all BPR engagements result in achieving cost reduction, and unless done with a strategic perspective, do not necessarily lead to better processes. Resistance to change is natural, and success of any program is in effective implementation. Here, we look at 10 key essentials for succeeding in BPR initiatives.

1. Look at the big picture

It is always the last piece of the Rubik's cube that takes most time to fix. And invariably, organizations tend to see the problem through that narrow window. More often than not, we are requested to look at improving processes at department A or function B to help bringing efficiencies, where there is an 'assumed' inefficiency. But what is clearly missed in these situations is the big picture. What are we attempting to achieve through the exercise? Is it cost reduction for the enterprise or reduction in turnaround time for a specific unit? If it is the former, then clearly we are missing the woods for the trees. Corporations should work backwards from the customer (external or internal) to determine how best to meet their needs. They need to focus on the strategies and tactics that really matter to customer satisfaction. Every company, in order to survive, is going to have to get better and better at delivering quality products to customers, fast and at acceptable prices. This is how the customer defines value. Anything less indicates a dysfunctional organization.

It is imperative for having a holistic approach on process improvement initiatives. Do not underestimate the opportunities that may lie in the entire supply chain, or for that matter even in marketing or sales functions or even business support units like Finance or IT. Sometimes process improvements exercises are also undertaken to achieve objectives of better control and risk management, and unless the 'big picture' is seen, one may result in chasing the proverbial 'wild goose'. For instance, when you are faced with customer complaints on timely delivery, irrespective of how much one improves the production and logistics/delivery processes, if there are bottlenecks involved in, say, inventory management, you would still end up with the same customer service issues!

2. Approach “addressable” costs. Not all costs

While it is critical to have the 'big picture' in mind, the universal principle of 80:20 should lead the spirit any transformation engagement. 80% of improvements are brought about by less than 20% changes, and the trick is identifying these 20. There is a clear need to distinguish between what is “addressable cost structures” that can be improved upon, and not the entire cost model.

For instance, while raw material consumption may be key area for bringing about improvements, these need not necessarily mean that reduction in quantity consumed bears a solution. Key may be in supply chain, inventory management and wastage reduction. Determining the bottlenecks in each of these, will help in deciding which of them get classified to be “addressable” costs. Not all the cost elements of the P&L are necessarily candidates for improvement.

3. Eliminate first. Prioritize next.

It is critical to focus energies on where the meat is. A simple principle to follow is to eliminate processes which are obvious candidates for rejection, and then starting to prioritize those that have potential for improvement.

It is quite obvious that processes that are governed by regulation or those required for control are not worth pondering over. Again, every initiative is successful only if is done in time, and meets the larger objective. Eliminating processes with minimal improvement potential from the scope of a BPR engagement is an important prerequisite for driving change in the desired timeframe.

Once the processes to be improved are identified, it is again important to prioritize them from both quantitative and qualitative perspectives. Quantitative because the impact of improvement needs to be sufficient to justify the change, and qualitative because the ease of change determines success of implementation.

4. Address the problem not the symptom

It is quite a natural tendency for organizations to address the symptom, which typically ends up being a short-term solution, rather than looking at the underlying problem. The issue becomes even larger when the short-term fix becomes an additional burden on the process, while the long-term issue continues to remain.

A classical example in our experience was at a leading retail chain, where longer customers queue time was impacting customer satisfaction. Closer analysis revealed that cashiers were, on average, manually typing in 10% of barcodes due to system updation related errors. While an IT fix could ultimately solve the problem once and for all, the approach adopted by the retailer of adding more checkout counters only created another complexity to address!

5. Breakdown processes into smaller parts

It can be quite a task to pin down a defective process at a high level, unless one breaks it down to activities, and carefully review the steps involved within each activity. Breaking down the entire process chain into smaller parts, and having an eye for detail is the critical factor here.

A very interesting example was where we encountered a Bank complaining of its losing to competition on loan processing turnaround time. The overall process that they followed was quite in line with industry practices, and yet there seemed to be a challenge on the TATs. After a careful review of the steps involved, the issue seemed to be simple: each of the customer applications was required to be photocopied at the central office before it got processed, and there was only 1 photo-copier attended to by 1 person! The problem got immediately fixed.

6. Avoid “pre-conclusions”. Validate change needs with actual data.

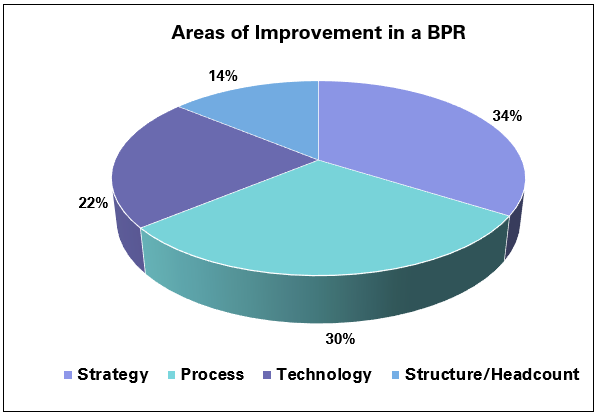

It is not too uncommon to see managements pre-concluding with standard fixes when they see costs escalate. For instance, most BPR exercise especially in developed markets look at addressing bottom line improvements through a headcount reduction. Just because personnel costs have a big share of the overall cost structure, it does not mean retrenchments could achieve the intended objective. Instead, it may result in pressure on existing staff and challenges the overall competitiveness. In our experience, manpower reduction can be one of the areas to look at, and even then, may at best help in 10% of the expected improvement. Clearly, the need is to look at how you improvise distribution, sales management, inventory management and improving material workflow. This is not only long term, but also becomes a sustainable model for improved efficiencies.

Also, when one looks at addressing one issue through a process improvement, it is important to ensure it does not create another. Centralizing dispatch, for example, may address the issue of logistical inconvenience. But it is important to make sure that it does not lead to turnaround time issues or compromises on security! Validating the hypothesis (of the new process bringing in the improvement) needs to be tested with actual data - if required on a pilot run basis, is critical before fully implementing.

7. Map impact of change with effort involved.

Change also needs to be driven by effort involved in getting it done. While it does make a lot of sense in getting changes that have the maximum impact with minimum impact implemented first, most organizations fail to identify these. Outsourcing non-core functions is a classical example. We still do see firms invest serious amount of money on in-house IT infrastructure management and system development while it might be much more effective and efficient to look at outsourcing some of these. Interestingly, having a merchandiser own the inventory at the shelf at a retail store could save significant inventory costs, and the ease of implementing this is straightforward.

On the contrary, it is not uncommon to see high levels change management efforts being drained on low impact initiatives. We were shocked to see a big retailer with a large branch network investing millions to get its P&L report on a real-time basis. Clearly, the benefit derived of the exercise did not justify the effort that went behind it.

8. Build overall ownership drive through participative approach.

No change is easy to implement unless you drive it through business participation. Resistance to change is expected but getting it past calls for investment of effort in educating the benefits to key stakeholders. Even if changes are imposed, the sheer negative dissonance to prove the initiative wrong will undo all the investment of time and effort. It is much more effective, and relatively easier, to take key stakeholders along through changes. Essentially, ownership to any change management achieves 3 things:

- Acceptance to change process, and participation

- Easier to demonstrate change impact in a more tangible manner

- Build sustainability to the change, and help build efficiencies in the long run.

9. Plan changes in sequence: not all changes at same time

When implementation exercises are undertaken for a large BPR initiative, they can bring about changes in the people, processes and structure. If there are too many changes too sudden, and happen around everywhere, it will be a recipe for failure. What is important here is make sure changes happen in a logical sequence, and happen without disruption to the existing operations. The exercise should always have a positive impact, even if they come in parts. Negative impact, even if temporary, can lead to challenges.

The simple rule to follow here, is to address the low effort changes first, demonstrate positive changes, and then take up the high effort changes. Having a core team to participate, and ensuring a constant feedback mechanism is put in place are other key factors to bear in mind.

One of the biggest mistakes companies make is over-reliance on IT solutions. Many are spending huge sums and taking giant leaps of faith without the proper foundation. Organizations must pay attention to all aspects of their operation, including people, products, processes and materials. In many cases, companies simply automate processes that are highly ineffective in the first place. This not only costs a lot of money, but the psychology of it all makes it hard to change once the investment is made.

10. Validate new processes with changes in context: continued improvement.

While a good process re-engineering exercise can yield dramatic results in a short time, they are not a permanent fix to ensure competitive processes, Every change has a reference to context. What might be the right thing to do, in say a stagnant macroeconomic situation, may not apply when there is a boom in the market. While it might a brilliant cost saving idea to have centralized purchasing process in a specific country retail model, it might be a disaster when the company decides to expand to other geographies. All processes and their relevance need to be seen in the context of the operating arena. There is no single fix for all problems at any point of time, and the same fix may not apply to the same problem at all points of time.

It is important to validate each of the process improvements periodically to ensure they do deliver what it was intended to. Continuous improvement is a way of life for many leading organizations. Consistency of a static process is no virtue in a dynamic marketplace!

To read more such insights from our leaders, subscribe to Cedar FinTech Monthly View